Descriptions

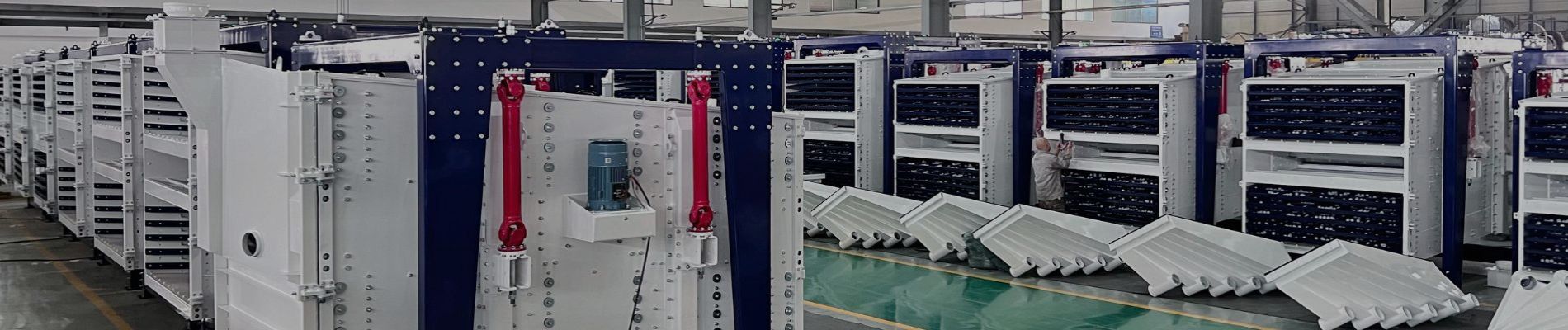

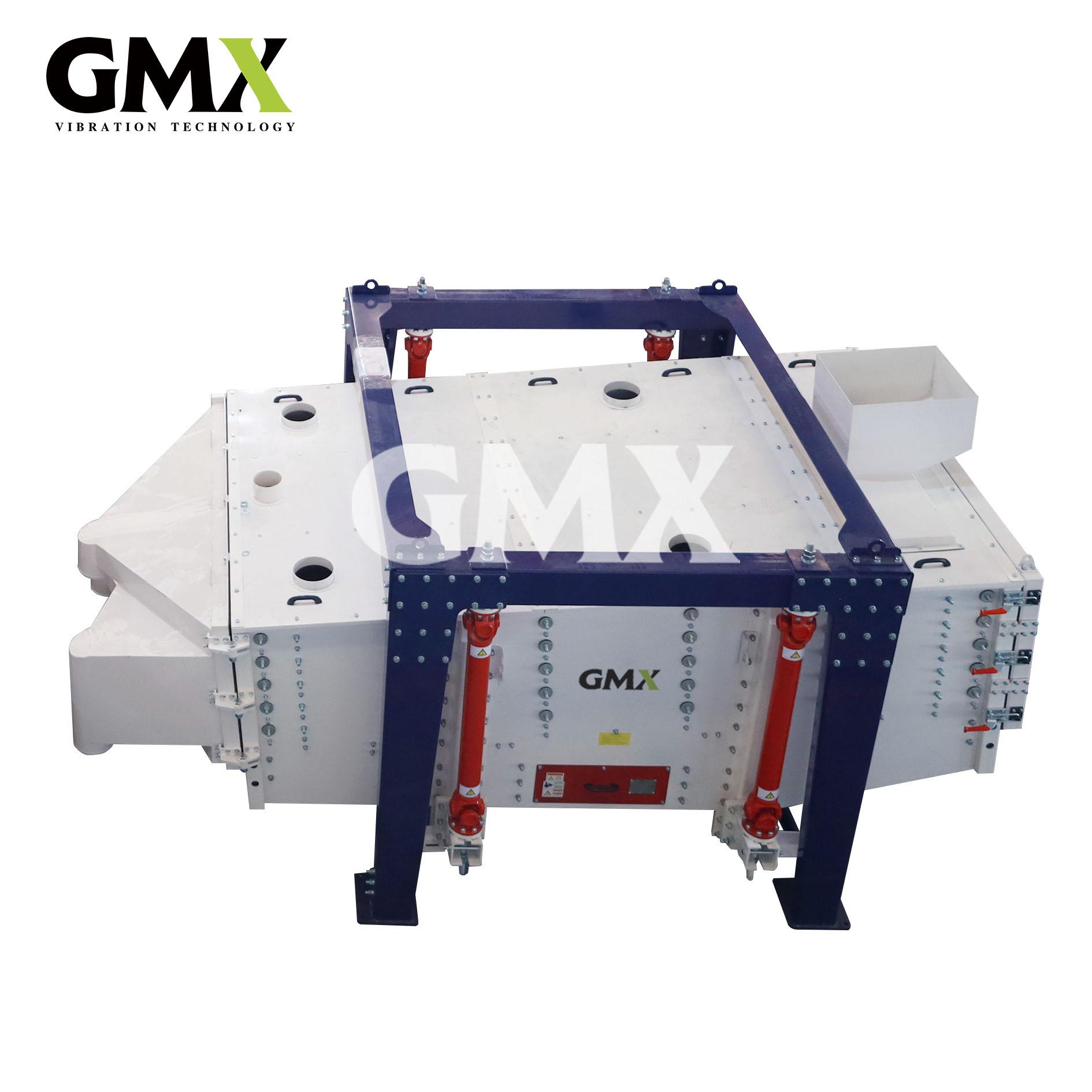

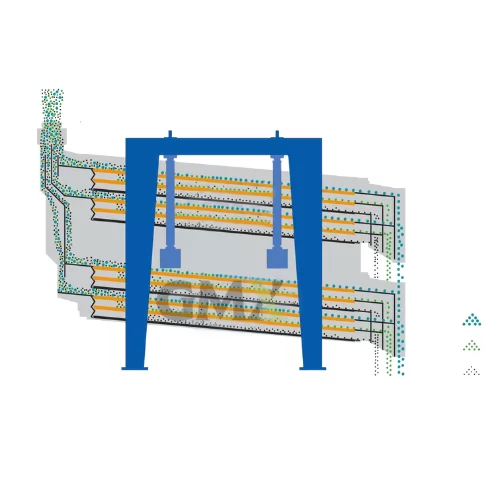

The GS series is an advanced industrial screening machine that generates a lowangle gyratory vibration motion close to a level plane, moving in a reciprocating side-to-side pattern. The largest model in this series offers a screen area of nearly 7.2m² per layer and can be customized with a multi-channel design and up to 12 screen layers. The unique design provides a high-throughput screening solution for industries requiring precise screening.

Features & Advantages

Enhanced Capacity

The GS series is designed to provide maximum screening capacity for every square foot of screen area.

-

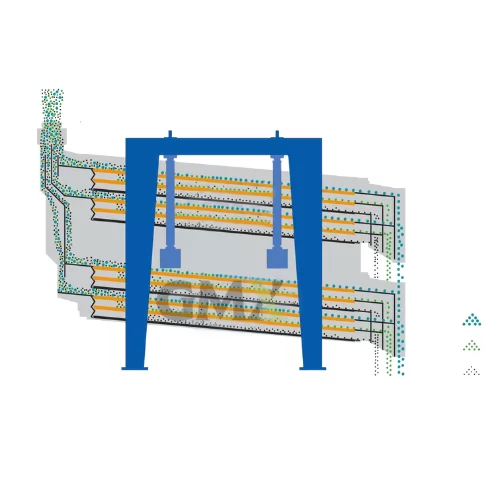

The largest model in the GS series offers up to 12 screen layers, each with a screen area of nearly 7.2m². This machine can be customized with a multi-channel design to double its capacity.

-

The GS series achieves a maximum rotation speed of 320 RPM, significantly surpassing the 180 RPM limit of conventional large screeners.

High Screening Efficiency

-

The feed box design ensures that powder materials are evenly distributed across each channel and spread evenly before contacting the screen.

-

The unique gyratory motion allows materials to remain on the screen longer, ensuring optimal screening effectiveness.

Quick Screen-change System

-

The GS series is equipped with hinged doors on both sides, allowing operators to quickly open and lock the system with effective dust control.

-

Screen tensioning devices make it easy for operators to install hook-style screens inside the machine and adjust the tension from outside.

This system enables two operators to inspect, replace, and tension a screen within minutes, significantly reducing downtime and boosting productivity.

Less Blinding

-

Each screening layer is equipped with hundreds of high-elasticity silicone bouncing balls, optimally distributed as spherical and irregular shapes within each grid.

-

The gyratory motion drives the captive balls to strike the underside of the elements repeatedly, clearing trapped sticky particles and near-sized obstructions.

Longevity and Durability

The maintenance-free high-performance drive and dynamic hanger system ensure that the GS series is built for long-lasting, reliable operation across various applications, requiring minimal maintenance.

Perfect Dust-Proof

The feed box door and discharge door are equipped with customized internal seals, and flexible sleeves are used to connect the inlet and outlet.

This configuration provides complete dust-proofing, ensuring sanitary operation and preventing foreign matter intrusion.

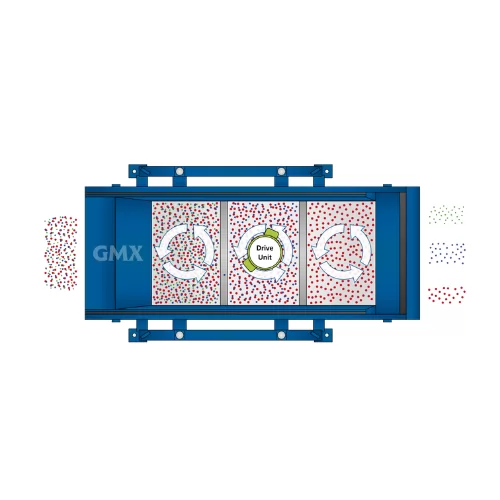

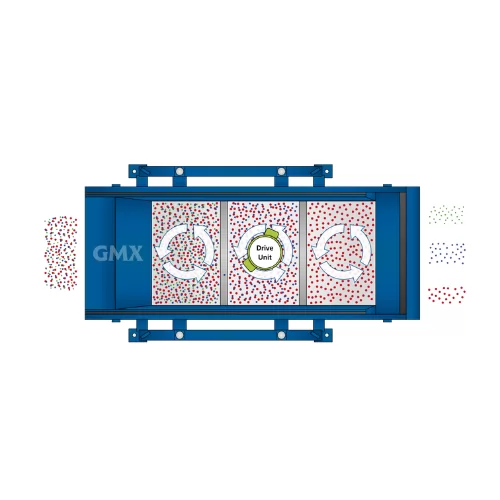

GMX Gyratory Motion

The centrally positioned drive unit in the GS series generates a gyratory motion across the entire screener, increasing material retention time and ensuring thorough contact with the screen surface.

This unique motion not only enhances screening efficiency but also protects fragile materials from damage.

Additionally, the GS series enables rotation speed and stroke adjustments tailored to material characteristics, maximizing screening performance.

Specifications

Datasheet

|

Mesh opening |

150 mesh - 5mm |

|

Max capacity |

20 t/h |

|

Operating speed |

280-320 rpm |

|

Screen slope |

5° |

|

Anti-blocking devices |

Bouncing balls |

Types

|

Types |

|

GS 50 |

GS 70 |

|

Mesh surface / deck |

mm |

150×360 |

200×360 |

|

Engine performance |

KW |

5.5 |

7.5/11 |

|

Weight |

t |

3.6-5.1 |

4.6-9.5 |

|

No. working streams |

|

1 |

1-4 |

|

No. screen decks |

|

1-6 |

1-12 |

Dimensions

Measurement

|

Types |

|

A

(Overall Length) |

B

(Overall Width) |

C

(Overall Height) |

|

GS50S11 |

mm |

4,200 |

2,260 |

1,585 |

|

GS50S12 |

mm |

4,243 |

2,260 |

1,720 |

|

GS50S13 |

mm |

4,253 |

2,260 |

1,855 |

|

GS50S14 |

mm |

4,450 |

2,260 |

1,990 |

|

GS50S15 |

mm |

4,530 |

2,260 |

2,125 |

|

GS50S16 |

mm |

4,650 |

2,260 |

1,990 |

|

GS70S11 |

mm |

4,300 |

2,720 |

1,482 |

|

GS70S12 |

mm |

4,320 |

2,720 |

1,617 |

|

GS70S13 |

mm |

4,117 |

2,720 |

1,748 |

|

GS70S14 |

mm |

4,373 |

2,720 |

1,880 |

|

GS70S15 |

mm |

4,570 |

2,720 |

2,125 |

|

GS70S16 |

mm |

4,690 |

2,720 |

2,260 |

|

GS70S21 |

mm |

4,823 |

2,720 |

1,942 |

|

GS70S22 |

mm |

4,854 |

2,720 |

2,210 |

|

GS70S23 |

mm |

4,866 |

2,720 |

2,710 |

|

GS70S24 |

mm |

4,900 |

2,720 |

3,000 |

|

GS70S25 |

mm |

4,838 |

2,720 |

3,232 |

|

GS70S26 |

mm |

4,887 |

2,720 |

3,435 |

|

GS70S31 |

mm |

4,821 |

2,720 |

2,235 |

|

GS70S41 |

mm |

4,814 |

2,720 |

3,232 |